Functions of non-woven geotextiles

1 Filtration

One of the main roles of non-woven geotextile in engineering applications is filtration. Good water permeability, soil retention so that non-woven geotextile in the rock project can be used as a filter layer instead of gravel particles to play a filtering role, to avoid the loss of soil particles, water pressure caused by excessive soil instability, non-woven geotextile filtration layer of the scope of application, including landfill leachate collection system, landfill closure, tailings ponds, reservoirs, dams, retaining walls, drainage, traffic and other aspects. In the application, the non-woven geotextile and need to filter the liquid direct contact, so the main considerations need to filter the liquid acidity, alkalinity, corrosivity and other factors for selection. Polypropylene staple fibre needle punched seven geotextile has good acid and alkali resistance, which is conducive to the long-term effective operation of the project.

2 Drainage

Non-woven geotextile is a sheet and has a certain thickness of the fibre aggregate, has good water collection performance and lateral drainage performance, placed in the soil body can be in the soil body in the water convergence, and then the water along the geotextile lateral discharge of the soil body. This characteristic of non-woven geotextile makes it possible to be applied in horizontal drainage under filling, vertical and horizontal drainage of earth and rock dam body and dam base, soil slope drainage to dissipate super pore water pressure, soft ground drainage and other projects. When the non-woven geotextile is mainly used for drainage, the selection of thick non-woven geotextile can achieve better desired goals, at this time, the mechanical properties of non-woven geotextile is not demanding.

3 Protection of geomembrane

In the seepage control project, seepage control layer using HDPE (i.e., high-density polyethylene) geomembrane, according to the design requirements, will be in the HDPE geomembrane on the laying of a layer of non-woven geotextile with a density of not less than 600 g/m² as a protective layer, HDPE geomembrane under the need to pave non-woven geotextile as a protective layer. When the landfill is not covered, the non-woven geotextile can protect the HDPE geomembrane from the aging effect of ultraviolet rays; in the landfill and after the landfill, the non-woven geotextile can protect the HDPE geomembrane from the damage of the sharp objects under the lower part of the state of long-term loading and the friction damage caused by the sudden uneven load bearing. The UV resistance of the non-woven geotextile itself is related to its thickness. Polyester spunbond needle punched nonwoven geotextile has superior UV resistance, compared with polyester staple fibre needle punched nonwoven geotextile, the effect of ultraviolet light on the former mainly occurs in the surface fibre.

4 Isolation

In engineering design, often encounter two different particle size materials in contact with each other. In order to prevent the two materials with different particle sizes from infiltrating each other under the action of water, lose the significance of the design structure, ensure the normal operation of the project, will be placed between the two materials between the isolation layer non-woven geotextile has high strength, good water permeability, has a certain thickness, can meet the needs of engineering design. For example, in China's independent research and development of CRTS Ⅲ type plate ballast track design, polypropylene staple fibre non-woven geotextile as an isolation layer set between the roadbed plate and the base, mainly to avoid the deformation of the bridge superstructure will be transferred to the roadbed plate, so that the warping and deformation of the bridge, and at the same time, has a certain degree of heat insulation, vibration isolation effect.

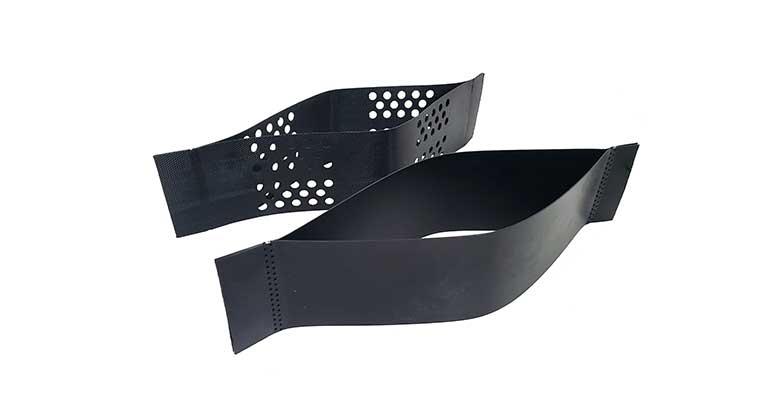

5 Reinforcement

Generally, non-woven geotextiles are used in the less demanding reinforcement projects, such as reinforced soil structure, soft base treatment of the reinforced mat. Reinforcement is the use of non-woven geotextile tensile properties to improve the mechanical properties of the soil, limiting the soil body in the long term use of the process of displacement. This is a high demand on the various mechanical properties of nonwoven geotextiles, and endothelium nonwoven geotextiles are more excellent in this regard. In geotechnical engineering design to select the appropriate non-woven geotextile need to be comprehensively determined from two aspects: one is the role and purpose of the non-woven geotextile; the second is the engineering situation. When the main role of filtration, and need to filter the liquid close to neutral, can choose polyester needle punched non-woven geotextile. When not only the role of filtration, but also a certain isolation, reinforced role, and need to filter the liquid for non-neutral, should choose high strength: acid and alkali resistance performance of polypropylene non-woven geotextile.