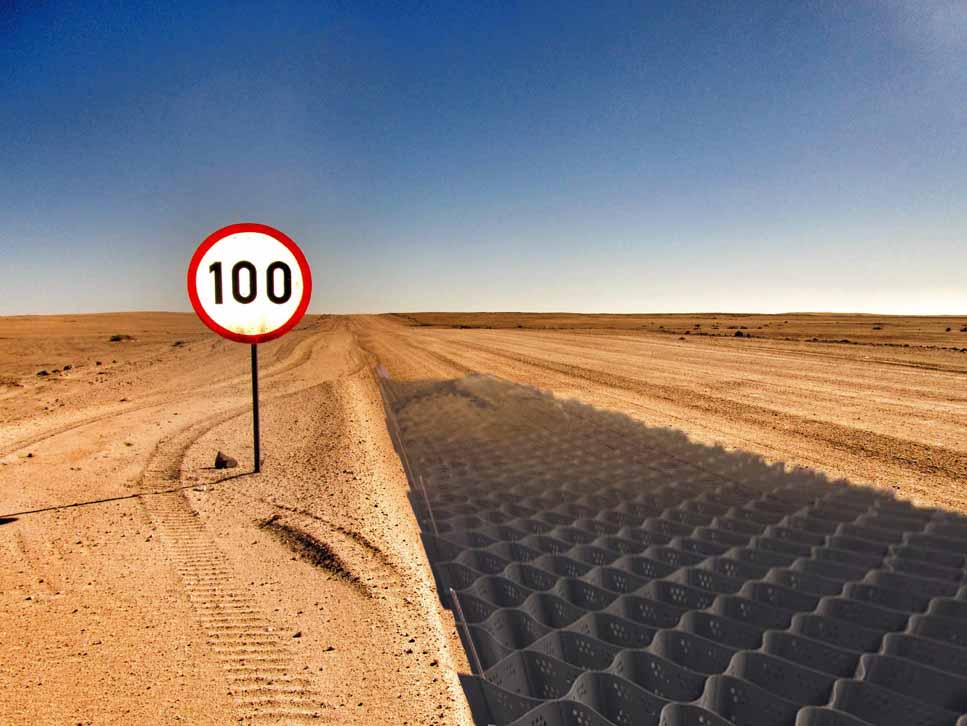

Application of geocells in ecological construction of highway projects

In recent years, there has been a growing focus on integrating ecological protection with engineering projects, especially in highway design. The goal is to ensure that highways not only serve as transportation corridors but also harmonize with the surrounding environment, enhancing slope stability and reducing environmental impacts like erosion and noise. Geocell Characteristics: Constructed from durable HDPE, forming a 3D cellular grid. Lightweight, corrosion-resistant, and easy to transport and install. Provides strong lateral confinement and anti-slip properties, enhancing slope integrity. Ecological Protection Mechanism: Geocells stabilize slopes by confining soil or growth media, promoting vegetation growth. Facilitate rainwater infiltration, reduce erosion, and protect plant roots, contributing to long-term slope stability and environmental benefits. Key Considerations: Follow product guidelines for selection and storage of geocells. Optimal slope gradient should not exceed 1:1, with excavation heights limited to 8-10 meters. Ensure proper thickness and compaction of fill materials within cells. Avoid construction during rainy seasons to prevent washout. Select suitable local vegetation and manage irrigation and drainage effectively. Overall, geocell technology offers an eco-friendly solution for slope protection, combining mechanical reinforcement with ecological restoration to support sustainable infrastructure development.