Geocell laying construction control

1、Preface

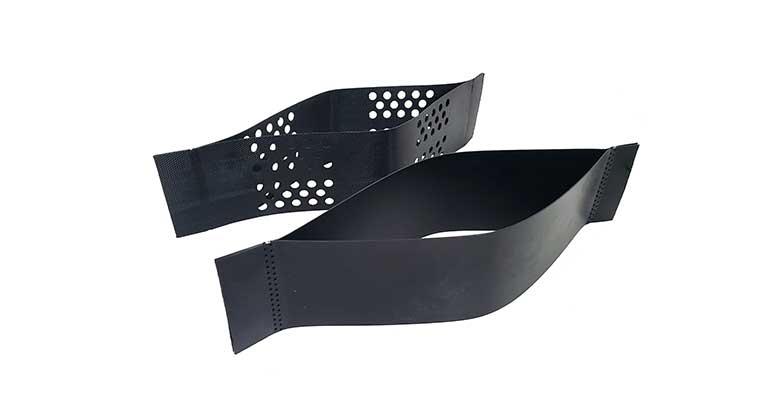

Geocell is a new type of geosynthetics material, made of high-density polyethylene strips, unfolded as a grid, each piece of unfolded contains several independent cells. In the chamber filled with gravel material, vibration compaction constitutes a reinforced bedding layer.

Geocell is made of high-strength HDPE or PP copolymer broadband, after strong welding or riveting and the formation of a piece of mesh chamber structure. Its main functions: reinforcement, isolation, restraint and load reduction. Can be in the lattice chamber of the soil particles to give three-dimensional constraints, so that the soil particles and the lattice chamber becomes a rigidity much greater than the foundation of the whole, it can be better distribution of the load applied on it, so that the foundation is more uniform and thus improve the bearing capacity of the foundation. Therefore, the laying of geocell material construction quality control is particularly important.

2. Quality control requirements

2.1 The quality of raw materials shall be sampled and inspected according to the specified frequency and standard, and the quality shall meet the design requirements, no aging, no breakage in appearance, and no pollution; it is required to strengthen the protection during construction to prevent pollution and damage.

2.2 The surface of the lower bearing layer of geocell should be levelled and compacted (compaction test passed), and hard protrusions on the surface should be removed.

2.3 When laying geocell, the direction of high strength should be placed in the main stress direction of embankment, and when the design is made by special requirements, the geocell should be laid according to the design.

2.4 Geocell materials should be paved close to the lower bearing layer, laid, tensioned and fixed according to the design and construction requirements, with the lap and anchor width meeting the requirements, and timely covered with fill materials meeting the requirements.

2.5 It is strictly prohibited to grind and transport equipment, etc. directly on the geocell materials or walking operations.

2.6 The paving of geosynthetics is a hidden project, the construction process should be monitored by the quality inspection personnel on the spot and make a good record of the hidden project inspection, and report to the Supervisor for signing before proceeding to the next process of construction.

3、Geocell Paving process

Hydraulic rammer reinforcing step→cleaning up the imaginary soil in the step part→secondary levelling and rolling of the sub-bearing layer→U-type nail processing→fixing the geocell on the inner side of the step→tensioning the geocell in the transverse and longitudinal directions→fixing the geocell→quality inspection of geocell installation→backfilling with gravel→levelling and rolling→acceptance inspection of the roadbed

4. Comparison of characteristics

4.1 Geotechnical laying laying tool laying characteristics

(1) L hook vertical hook 11cm make 10cm high geocell close to the L hook vertical hook, vertical vertical spreading, to avoid folding, twisting, bending deformation.

(2) The two sides and rear of the geocell are nailed and unfolded with U-shaped steel bars, and the working principle of the geocell laying tool is adopted in the front, which is tightened under the guarantee of the designed tensile force. This can make the geocell straighten, tighten and smooth under the state of overall stress; ensure that the load is applied in a good state of overall stress to avoid local stress damage to the geocell.

(3) The height of the travelling system is 13cm, which ensures that the geocell is close to the sub-bearing layer, avoiding the phenomenon of high convex warping.

(4) The triangular stabilising frame can transfer the force evenly to the main rod, and play a supporting and protecting role for the main rod, so that the main rod is not easy to deform under the action of load.

(5) Save the construction labour, speed up the construction progress, ensure and improve the construction quality.

4.2 Disadvantages of artificial laying geocells

(1) The construction speed of artificial laying geocell is slow, and a lot of labour is needed to ensure the construction progress;

(2) The force of geocell is not uniform, and the construction quality is difficult to guarantee.