Research on rough geomembranes

Rough geomembrane (glossy geomembrane): It is a new type of waterproof building material used for seepage and moisture-proofing, which is made of high-density polyethylene resin by adding a certain proportion of carbon black masterbatch, anti-aging agent, antioxidant, ultraviolet ray absorber, stabiliser, etc. It is a new type of seepage and moisture-proof building material. Rough-faced HDPE geomembrane is a new type of seepage control and anti-corrosion material, which is widely used in various projects with seepage control and anti-corrosion requirements. It is made of high-quality HDPE virgin resin, the main component of which is 97.5% HDPE, about 2.5% carbon black, trace antioxidant and heat stabiliser, anti-ageing material, ultraviolet absorber, no other additives, fillers and expanders, and it is made by three-layer co-extrusion technology. The resins used are virgin high or medium density polyethylene resins specially formulated for geomembrane applications.

1 Basic information of geomembrane

Geomembrane (brown, glossy) usually refers to HDPE geomembrane, is a high polymer polyethylene materials, co-extrusion technology made of high-efficiency molecular density, liquid permeability is extremely low, anti-infiltration effect is excellent. Has excellent chemical stability, anti-aging, anti-ultraviolet, anti-decomposition ability, can be used naked, the service life of the material up to 50-70 years, there are a variety of specifications for a variety of laying forms to meet the requirements of different projects seepage control. Geomembrane seepage control can be widely used in domestic landfills, sewage treatment plants, chemical plants, oil refineries, petrol stations, storage tank seepage control, ash dumps, dissolution ponds, sedimentation ponds, yards, tailings bottom lining seepage control and other engineering needs, the application surface and its wide range [1].

Geomembrane (brown, glossy) has a high seepage control coefficient, good heat resistance and cold resistance, its use of environmental temperature of 85 ℃, low temperature -70 ℃. Can be used for a long time exposed and maintain the original performance, geomembrane using virgin polymer polyethylene plastic and carbon black particles do not contain any preservatives, in the use of safe and environmentally friendly no pollution. Geomembrane in the sewage seepage control problem, can prevent sewage pollution of the surrounding soil and environment, to protect people's life and health. Geomembrane transport and construction is more convenient, at the same time used in the seepage control system in the cost of the traditional reinforced concrete seepage control structure is 30% lower.

2 Seepage control geomembrane product classification

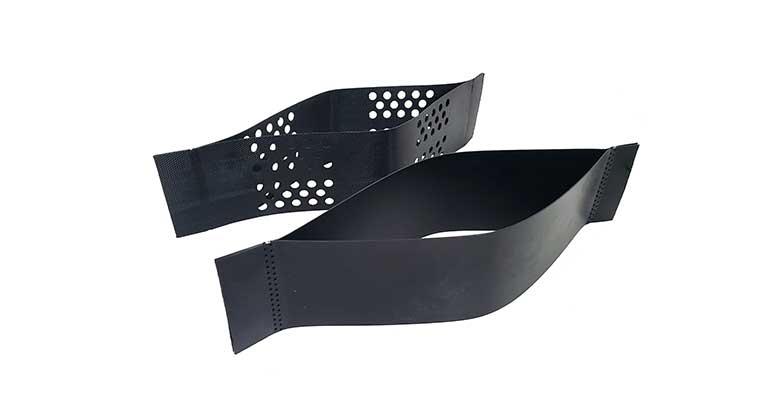

(1) According to the type of roughness is divided into: glossy geomembrane, single roughness geomembrane, double roughness geomembrane, post point anti-slip geomembrane, foot clamping geomembrane.

(2) According to the use of points, can be divided into: geomembrane, seepage control membrane.

(3) According to the use of raw materials, can be divided into: HDPE geomembrane (high-density polyethylene geomembrane), MDPE geomembrane (medium density polyethylene geomembrane), LDPE geomembrane (low density polyethylene geomembrane), MLLDPE geomembrane (metallocene geomembrane), EVA geomembrane.

3 Geomembranes (rough, glossy) Main applications

(1) HDPE geomembrane is suitable for environmental protection projects: such as landfills, sewage treatment plants, power plant regulating ponds, industrial, hospital solid waste landfill;

(2) LDPE impermeable membrane for water conservancy projects: such as rivers, lakes, reservoirs, dams, channels, horizontal seepage control projects;

(3) HDPE impermeable membrane in municipal engineering: underground, underground garage project, roof garden, sewage pipe seepage control;

(4) HDPE anti-seepage geomembrane for garden engineering: artificial lakes, rivers, golf course reservoirs and so on;

(5) HDPE geomembrane for petrochemical: refinery tank seepage control, chemical reaction pools, sedimentation tanks lining, secondary lining layer;

(6) HDPE geomembrane for the mining industry: heap leach tanks, dissolving pools, sedimentation tanks, tailings, such as the bottom lining seepage control;

(7) LDPE polyethylene geomembrane for transport facilities: highway foundation reinforcement, culvert seepage control;

(8) LDPE impermeable membrane for agriculture: seepage control of reservoirs, drinking water pools, water storage ponds and irrigation systems;

(9) HDPE membrane for aquaculture: aquaculture ponds, fish ponds, shrimp pond lining, sea cucumber circle slope protection;

(10) HDPE polyethylene impermeable membrane for the salt industry: salt crystallisation ponds, brine pools thatched cover, salt membrane;

(11) EVA geomembrane, also known as waterproof sheet, mainly used in tunnel seepage control;

(12) MLLDPE geomembrane is suitable for potash fertiliser industry in alpine area: sodium salt pool, potassium salt pool, lithium salt pool, etc..

4 Methods of production of brown-faced geomembranes

Rough-faced geomembrane is divided into two production methods, one is the production of glossy geomembrane is completed, the surface of the hot melt spraying, the advantage of the process is simple, the disadvantage is that the spraying of rough particles is easy to fall off, the particles that fall off pollute the environment, affecting the friction coefficient of the rough geomembrane. Another is the extrusion method to produce rough surface geomembrane, which is evolved from the production method of glossy geomembrane, and it requires great technical support [2]. The production of rough-faced geomembrane by extrusion method is realised in a three-layer total blown film unit, the double rough-faced geomembrane is an inner and outer layer injected with nitrogen and polyethylene mixture, and the middle layer is a high-density polyethylene raw material. Three-layer extrusion host will be heated and mixed with the material plasticised uniformly, after filtering the filter to remove impurities, through the three-layer moulding machine head extrusion moulding, through the low-pressure high-volume wind ring cooling and shaping, and then haulage dissected edges of the post-production of double rough geomembrane membrane membrane rolls. The main feature of the extrusion method of brown geomembrane is the physical method of high temperature and high pressure injection of nitrogen (blowing agent), inert nitrogen blowing agent and linear low-density polyethylene and high-density polyethylene to form a mixture, in the screw screw barrel heating and mixing pressure transport, nitrogen expansion and uniform distribution in the polyethylene raw materials, the formation of foam plastic embryo film, which is brown foamed raw materials accounted for the raw material of the total amount of 30% - 55% When the raw materials of the embryonic body are extruded out of the moulding head, the high-pressure inert nitrogen ‘explodes’ and spews out, forming a rough structure on the surface of the middle-layer high-density polyethylene film, which is in line with the geomembrane body material, and the rough surface is firm and the height of the roughness is adjustable and controllable, Density can be adjusted and controlled. The range of the number of roughness on the surface of the rough geomembrane and the height of roughness are controlled by controlling the injection rate of the foaming material (injection volume) and the speed of the extruder. The speed of the extruder is controlled by the high-torque frequency converter and the frequency converter motor to control the rotational speed of the extruding screw; the melting viscosity of the polyethylene raw material is controlled by changing the temperature of the screw processing process; and the amount of nitrogen injected is controlled by changing the flow rate of the inert gas and the pressure. The middle screw speed is adjusted according to the thickness of the geomembrane requirements, the processing temperature should be controlled according to the characteristics of the geomembrane raw materials, it is recommended that 175-220 ℃, the inert gas pressure is generally in the 30---50MPa. blowing agent is generally injected from the mixing section of the screw, and the amount of injection can be controlled through the flow meter[3].

5 Extruded rough geomembrane production characteristics

(1) Simple control of single and double-sided roughness, only need to control the valve of inert nitrogen injection for switching the inner or outer layer;

(2) The foaming agent is inert nitrogen, safe and environmentally friendly;

(3) The roughness height and density of rough geomembrane can be precisely controlled;

(4) Inert nitrogen and polyethylene mixture does not have chemical reaction, nitrogen in the head of the moulding machine all excluded, polyethylene material characteristics can be retained;

(5) The foam raw material layer and the base layer of geomembrane are the same raw material, and there is no problem of delamination when they are extruded together.

6 Selection of geomembranes, pay attention to several factors

(1) brown geomembrane transport issues: brown surface affects the diameter of the geomembrane coil, the same weight of brown geomembrane than ordinary glossy geomembrane coil warp 25% larger, choose a wide-body vehicles; products in the transport process pay attention to preventing rain, rain after the brown geomembrane, in the next step of the construction of the welded will bring other problems.

(2) According to the bidding documents and engineering needs, choose the appropriate geomembrane quality standards: non-standard geomembrane, the new national standard type I geomembrane and the new national standard type II geomembrane. Different projects require different specifications of the quality of the geomembrane, for example: landfill, seepage control requirements are high, so anti-acid and alkali, corrosion resistance, aging resistance, resistance to low temperatures, resistance to ultraviolet ability requirements, the need to buy higher than the standard geomembrane.

(3) According to the bidding documents and engineering needs, choose the appropriate thickness of the brown geomembrane: the thickness of the brown geomembrane from 1mm-2.0 mm ranging from different thicknesses of the brown geomembrane price is different, generally the thicker the brown geomembrane, the higher the price. Different engineering needs to choose a different thickness of geomembrane, not only to save costs, but also to facilitate construction.

(4) Select both the production of geomembrane products and construction qualification of geomembrane manufacturers: geomembrane manufacturers are numerous, the procurement must be more consultation, more comparison, or to the manufacturers directly visit. Manufacturers can produce products can also organise on-site construction, project quality can be guaranteed, to achieve ‘turnkey’ project acceptance.

(5) geomembrane construction projects are mostly outdoor projects, construction should choose the best spring.