SilkNet Geocell: Revolutionizing Geotechnical Engineering with Advanced Soil Stabilization Technology Introduction to SilkNet Geocell Technology

Introduction to SilkNet Geocell Technology

In the rapidly evolving field of geotechnical engineering, innovative solutions are constantly sought to address challenges such as soil erosion, slope instability, and infrastructure degradation. Among these cutting-edge technologies, SilkNet Geocell has emerged as a transformative solution for soil stabilization, ground reinforcement, and environmental protection. This article explores the science, applications, and benefits of SilkNet Geocell, positioning it as a cornerstone for sustainable infrastructure development in modern construction projects.

What is SilkNet Geocell?

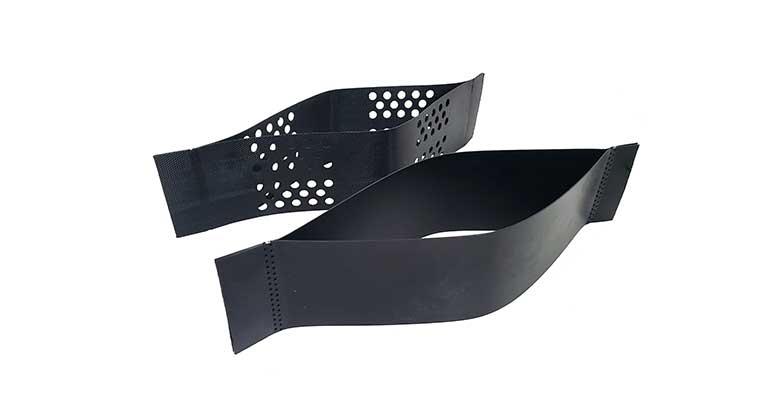

SilkNet Geocell is a high-performance geosynthetic cellular confinement system designed to enhance soil strength, improve load distribution, and prevent soil erosion. Composed of durable polymer materials, the system forms a honeycomb-like matrix (geocells) that encapsulates soil or granular fill, creating a reinforced structure. The term "SilkNet" refers to the product's ultra-lightweight, flexible, and corrosion-resistant properties, which mimic the structural integrity of natural silk fibers.

Key features of SilkNet Geocell include:

- High tensile strength: Resists deformation under heavy loads.

- Environmental adaptability: Functions effectively in diverse climatic conditions.

- Cost-effective: Reduces material and labor costs compared to traditional methods.

- Easy installation: Requires minimal machinery and can be deployed in remote locations.

How SilkNet Geocell Works

The core principle of SilkNet Geocell lies in its cellular confinement technology. When installed, the geocell modules are unfolded and anchored into the ground. Soil or fill material is then compacted into the cells, creating a three-dimensional matrix that significantly increases the soil's shear strength and stiffness. This confinement effect prevents lateral soil movement, distributes loads across a larger area, and minimizes deformation over time.

Mechanisms of Action:

- Load Redistribution: The geocell grid transfers weight from heavy loads (e.g., vehicles, machinery) to the stabilized soil layer beneath.

- Soil Reinforcement: The confined soil within each cell acts as a composite material, enhancing its bearing capacity by up to 10x.

- Erosion Control: The interlocking cells trap soil particles, preventing washout from water or wind erosion.

- Slope Stabilization: Installed on steep slopes, the geocell system prevents slippage and maintains structural integrity.

Applications of SilkNet Geocell in Geotechnical Engineering

SilkNet Geocell is a versatile solution applicable across multiple industries. Below are its primary applications:

1. Road and Highway Construction

- Roadbed Stabilization: Reduces pavement cracking and settlement by reinforcing subgrade soils.

- Temporary Roads: Ideal for construction sites and mining operations where heavy equipment causes soil compaction.

- Bridge Approach Slabs: Prevents differential settlement between the bridge deck and roadbed.

2. Erosion Control and Coastal Management

- Coastal Protection: Mitigates wave erosion and sediment loss in marine environments.

- Riverbank Stabilization: Prevents bank collapse and maintains watercourse alignment.

- Sediment Retention: Captures runoff and reduces pollution in water bodies.

3. Landfill and Waste Management

- Leachate Control: The geocell system prevents leachate migration by stabilizing landfill bases.

- Cap Liner Reinforcement: Enhances the durability of landfill covers against mechanical stress.

4. Mining and Industrial Infrastructure

- Tailings Dam Reinforcement: Strengthens dam structures to withstand heavy loads and seismic activity.

- Stockpile Stabilization: Prevents dust emission and soil displacement in material storage areas.

5. Agricultural and Environmental Projects

- Agricultural Terracing: Creates stable, erosion-resistant terraces for crop cultivation on slopes.

- Wetland Restoration: Supports ecological rehabilitation by stabilizing wetland soils.

Advantages of SilkNet Geocell Over Traditional Methods

Compared to conventional geotechnical solutions like concrete slabs or gravel beds, SilkNet Geocell offers distinct advantages:

| Feature | SilkNet Geocell | Traditional Methods |

|---|---|---|

| Cost Efficiency | 30–50% lower material costs. | High costs for concrete or asphalt. |

| Installation Speed | Deployed in hours vs. days for concrete. | Labor-intensive and time-consuming. |

| Environmental Impact | Recyclable materials and reduced carbon footprint. | High energy consumption and waste. |

| Durability | 50+ year lifespan with UV and chemical resistance. | Degrades faster under harsh conditions. |

| Adaptability | Works in wet, dry, and frozen soils. | Limited to specific soil types. |

Technical Specifications of SilkNet Geocell

To ensure optimal performance, SilkNet Geocell is engineered with precise technical parameters:

- Material Composition: High-density polyethylene (HDPE) or polypropylene (PP) with UV stabilizers.

- Cell Sizes: Customizable cell heights (50mm to 200mm) and widths (150mm to 300mm).

- Load Capacity: Supports up to 10,000 kN/m² (varies by cell size and material).

- Temperature Range: Functions in temperatures from -40°C to +80°C.

- Water Permeability: Designed to allow controlled water infiltration for drainage.

Installation Process of SilkNet Geocell

The installation of SilkNet Geocell follows a standardized procedure:

- Site Preparation: Clear the area of debris and level the ground.

- Geocell Unfolding: Lay out the geocell modules and interlock them using heat-welded seams.

- Anchor Fixation: Secure the edges with ground anchors or stakes to prevent uplift.

- Filling: Compact soil or gravel into each cell using a vibratory plate compactor.

- Final Inspection: Ensure uniform filling and check for defects.

Tools Required:

- Tape measure

- Welding equipment (for seam sealing)

- Compaction equipment

- GPS surveying tools for alignment

Case Studies: SilkNet Geocell in Action

Case Study 1: Highway Expansion in Arid Desert Region

A 150km highway project in the Sahara faced challenges with loose sand and frequent sandstorms. SilkNet Geocell modules with 150mm cell heights were installed to stabilize the roadbed. Results:

- Reduced pavement maintenance costs by 40%.

- Withstood 10 years of extreme temperature fluctuations.

- Prevented 90% of sand erosion.

Case Study 2: Coastal Protection in Japan

Following a typhoon, a coastal town used SilkNet Geocell to reinforce a 2km stretch of eroded shoreline. Outcomes:

- Slope stability improved by 70%.

- Reduced repair costs by $1.2 million annually.

- Enhanced biodiversity by enabling mangrove regrowth.

Environmental and Economic Benefits

SilkNet Geocell aligns with global sustainability goals by:

- Reducing Carbon Footprint: Requires 60% less energy than concrete production.

- Minimizing Waste: Recyclable materials divert plastic from landfills.

- Lower Lifecycle Costs: Long-term durability reduces frequent repairs.

Future Trends and Innovations

The geocell industry is advancing rapidly with:

- Smart Geocells: Embedded sensors to monitor soil stress and degradation in real time.

- Biodegradable Materials: Research into plant-based polymers for eco-friendly solutions.

- 3D Printing Integration: Custom-printed geocell structures for complex terrain.

Frequently Asked Questions (FAQs)

Q: Can SilkNet Geocell be used in freezing climates?

A: Yes, its thermal stability ensures performance down to -40°C.

Q: How long does installation take?

A: A 1,000m² area can be completed in 2–3 days with a 4-person team.

Q: Is SilkNet Geocell compatible with organic soils?

A: Yes, the system works with clay, silt, and sandy soils.

Conclusion

SilkNet Geocell represents a paradigm shift in geotechnical engineering, offering unparalleled efficiency, sustainability, and adaptability. As global infrastructure demands grow, this technology will continue to play a pivotal role in building resilient, cost-effective, and environmentally conscious projects. For engineers, contractors, and policymakers, adopting SilkNet Geocell is not just an innovation—it’s a necessity for the future of construction.