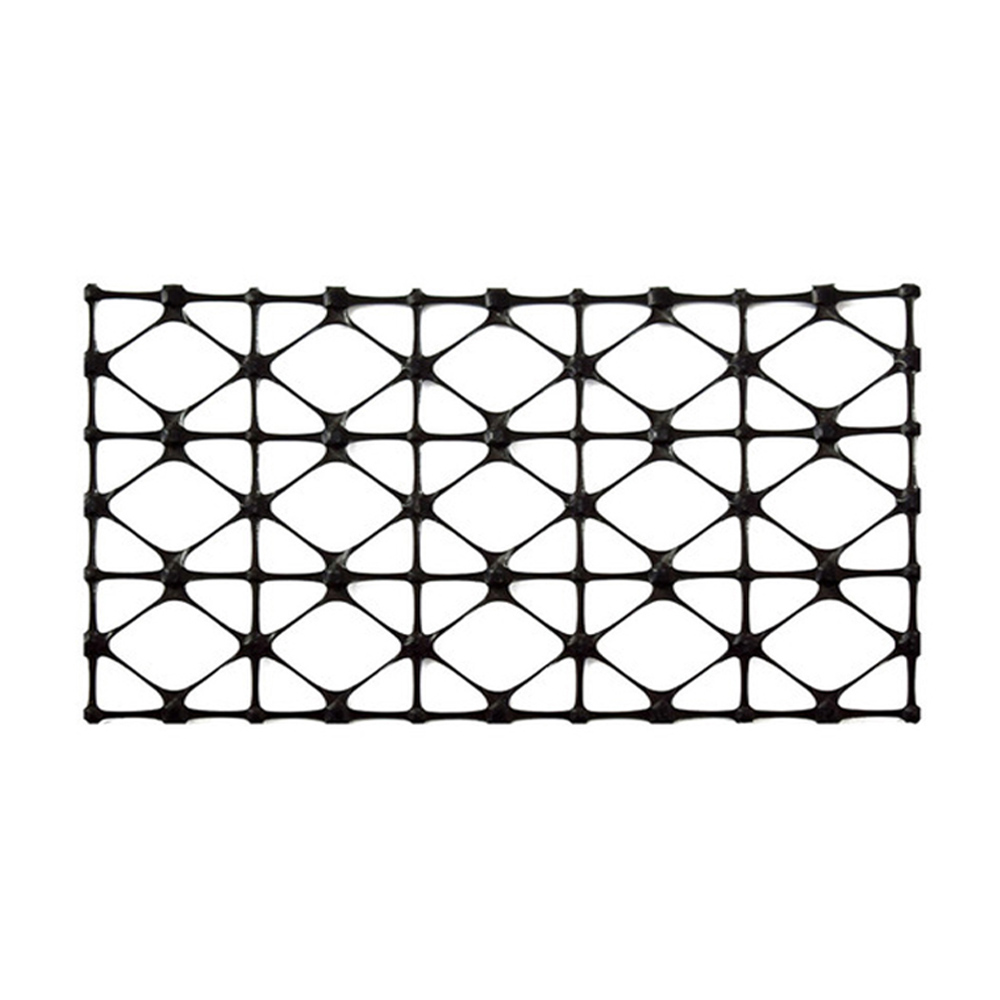

Multiaxial Geogrid

Multiaxial Geogrid is one kind of plastic geogrid with a stable network structure formed by extruding, punching, and four-direction stretching. Multiaxial geogrid provides the bearing capacity based on the four directions of the node position, which is more stable and efficient than other plastic geogrids.Multiaxial Geogrid is applied for the foundation reinforcement of airport, road, railway, port, etc.

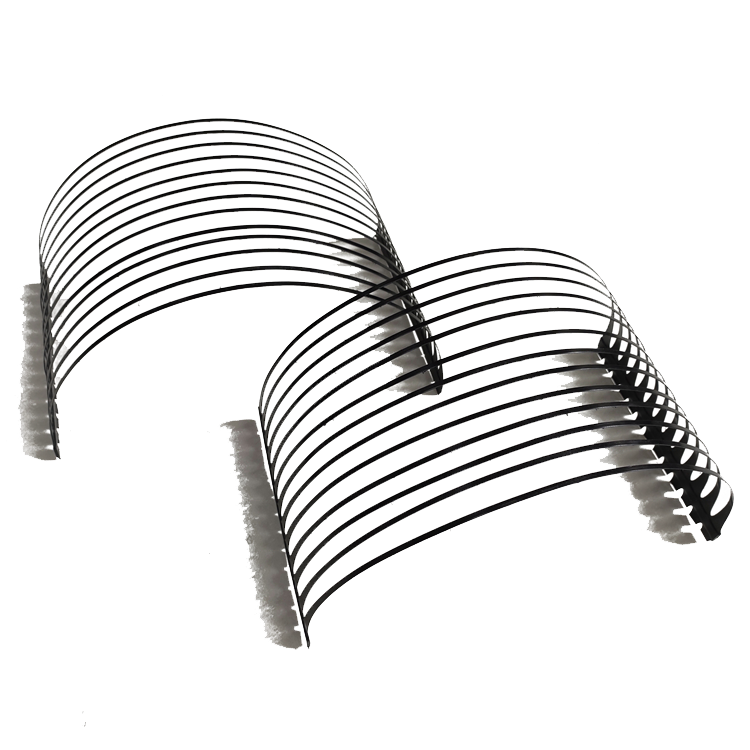

PP/HDPE Uniaxial Geogrid

Uniaxial geogrid,made of high molecular polymer,is extruded into sheet and then punched into regular mesh pattern,and finally stretched in the longitudinal direction.Uniaxial geogrid is mainly applied in highway,railway,slope protecting projects,retaining wall,dam to strengthen land loading caoacity and extend its service life. Features in reducing area,project cost and maintenance cost,convenient to construct.

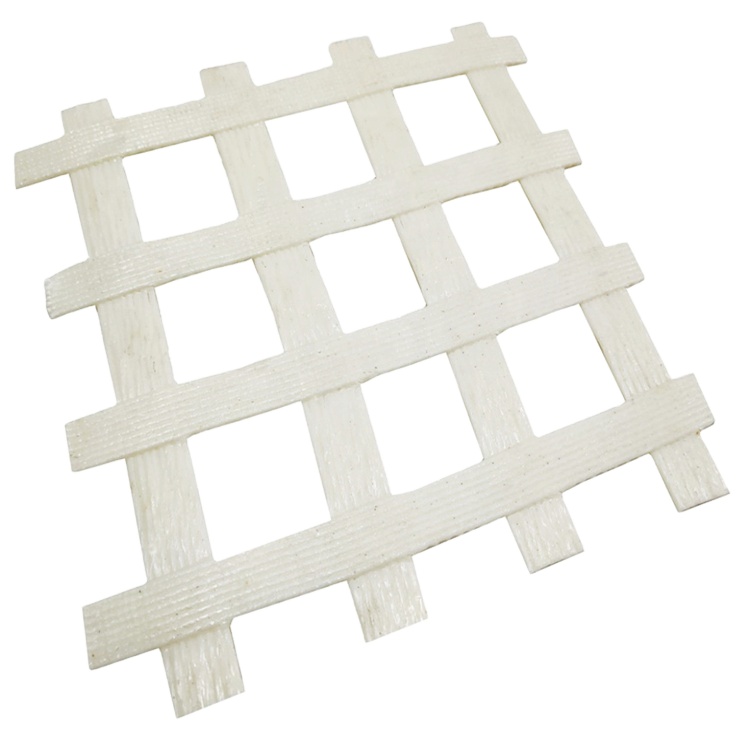

Fiberglass Geogrid

Fiberglass Geogrid is woven from glass fiber filaments and coated with bitumen to enhance bonding with asphalt layers. This reinforcement strengthens the asphalt layer, extends pavement service life, and reduces the occurrence of reflective cracking under cyclic traffic loads.

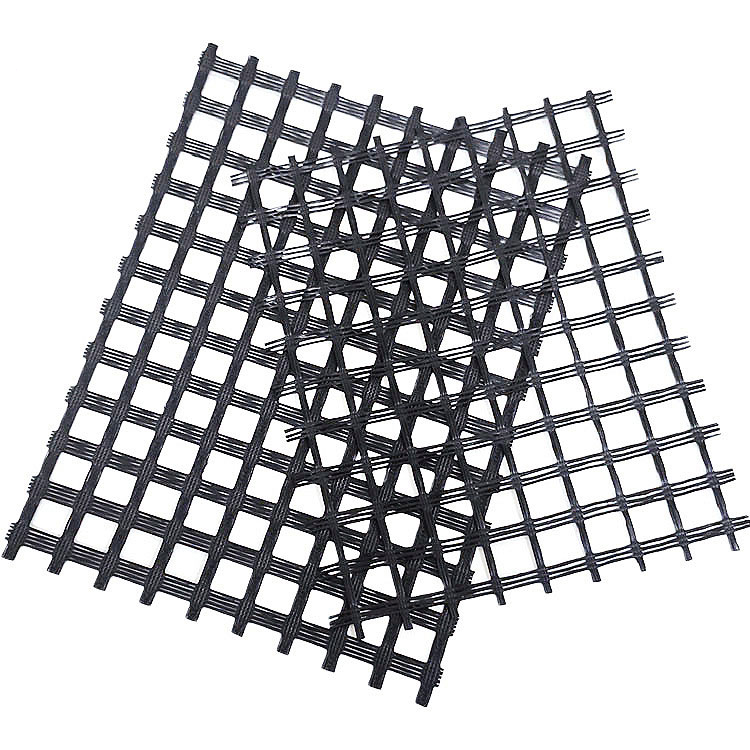

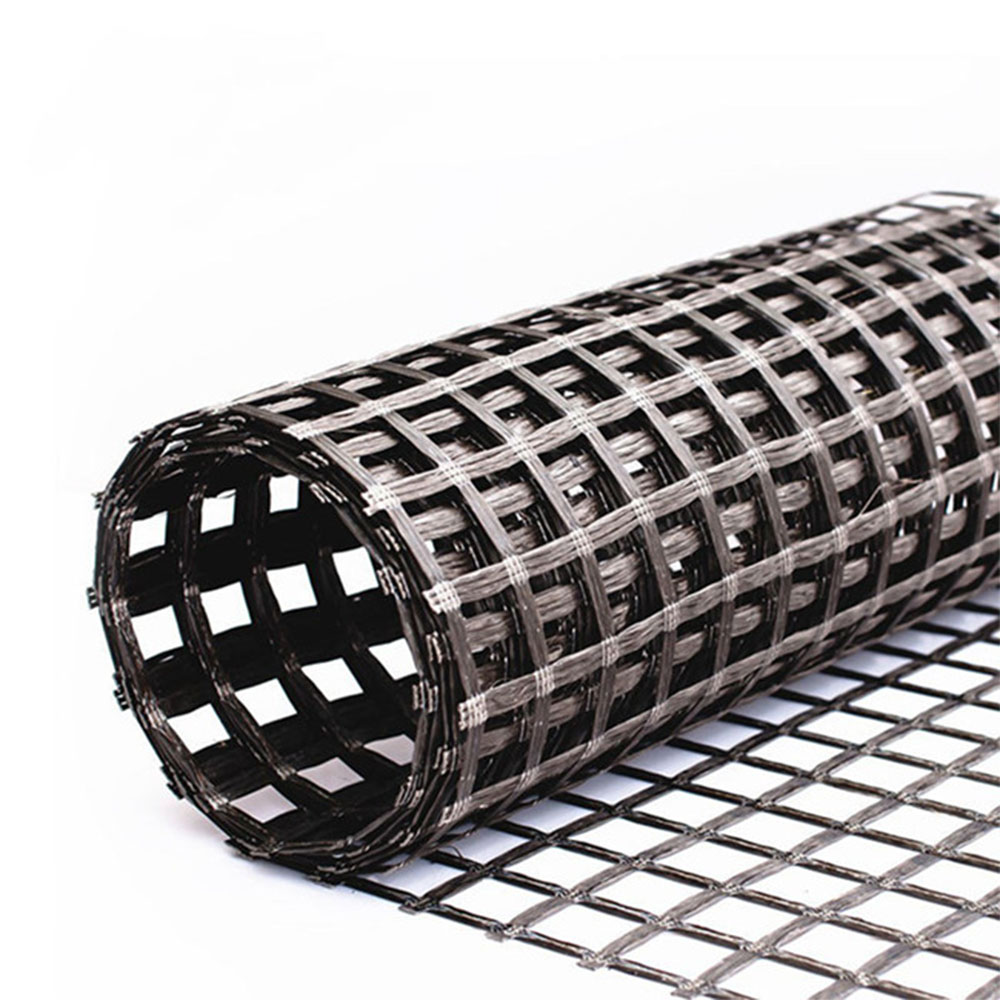

Polyester Geogrid

Polyester Geogrid is manufactured from high-strength polyester industrial yarns, formed into a warp-knitted structure, and coated with PVC. It is applied to reinforce soft soil foundations and subgrades,thereby improving project quality and reducing construction costs. This product is primarily used for stabilizing soft ground in railway and road construction projects.

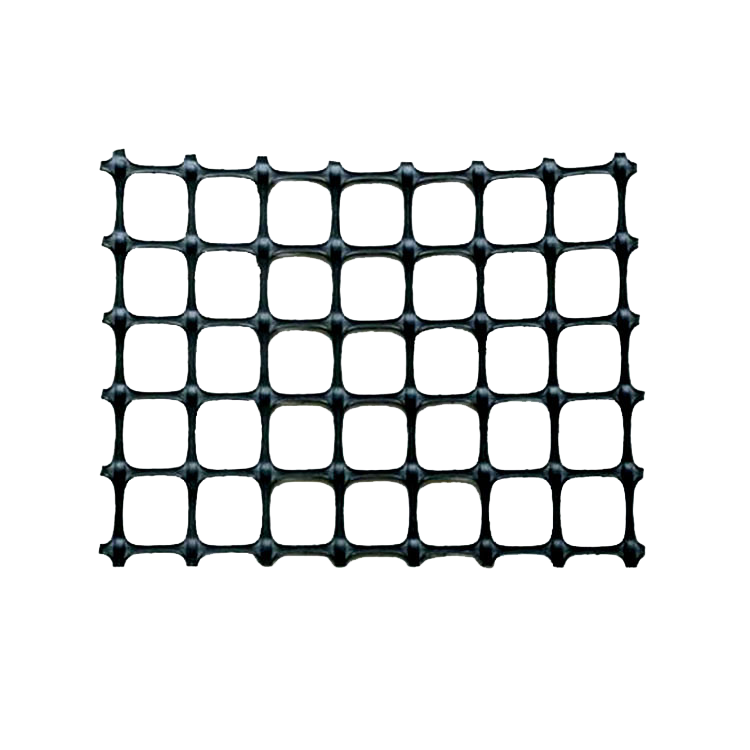

PP Biaxial Geogrid

PP biaxial geogrid is manufactured from PP. It is produced through the process of extruding, punching, heating, longitudinal and transverse stretching. PP biaxial geogrid is mainly applied in strengthening soft ground for railways, highways, slope protecting projects, airfields, and foundation reinforcement of large-area permanent bearing engineering fields. It can increase stability and loading capacity of the foundation/subgrade, and prolong its service life.

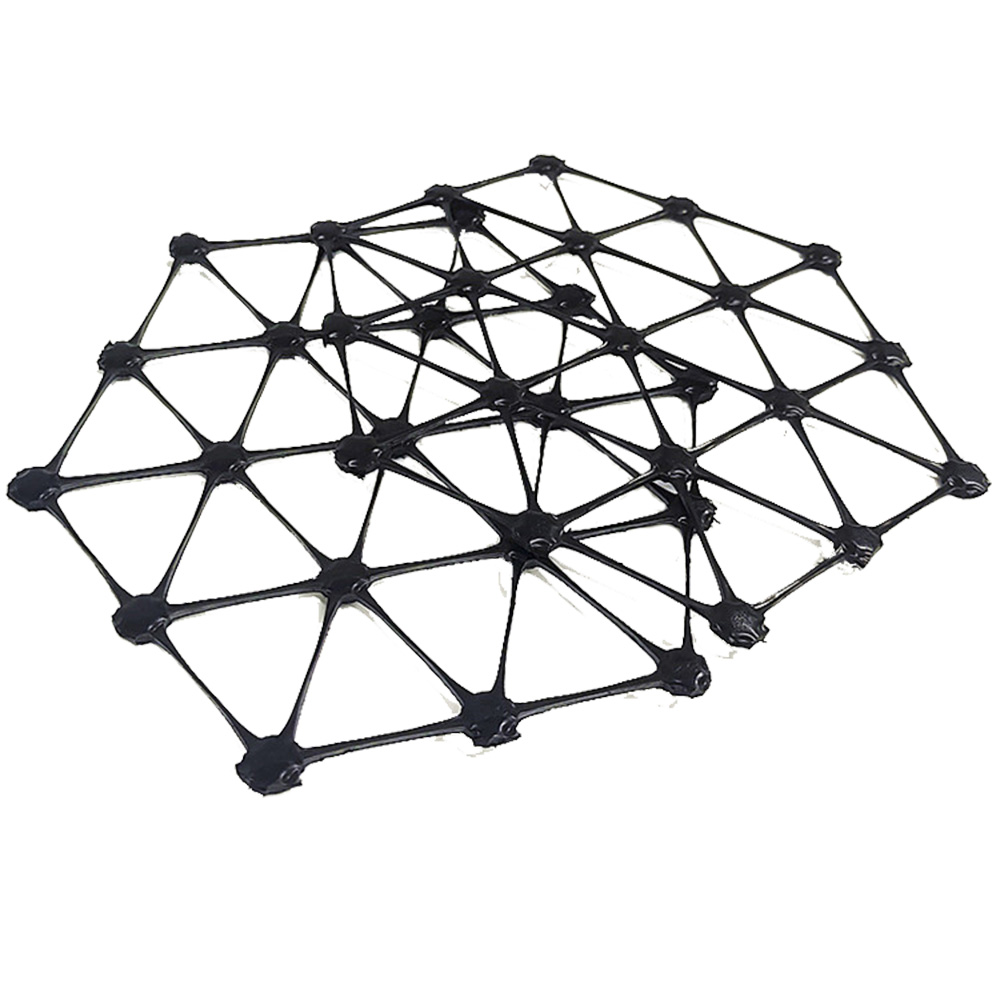

Triaxial Geogrid

Triaxial Geogrid is a kind of three-dimensional geosynthetic material which is braided by high strength polymer fibers. It forms a solid three-dimensional structure by setting transverse and longitudinal stiffeners in two vertical directions and connecting ribs in one horizontal direction. This structure enables the triaxial geogrid to disperse and withstand forces in multiple directions when subjected to external forces, thereby improving the stability and carrying capacity of the overall structure.

PP Mining Geogrid

PP Mining Geogrid is manufactured from modified polypropylene and other high-molecular polymers via extrusion and stretching processes. Designed primarily for underground mining scenarios, it is suitable for false roof support and roadway side support in coal mine and metal mine working faces. Additionally, it can be applied to support projects such as subways, tunnels, and other similar underground engineering works.

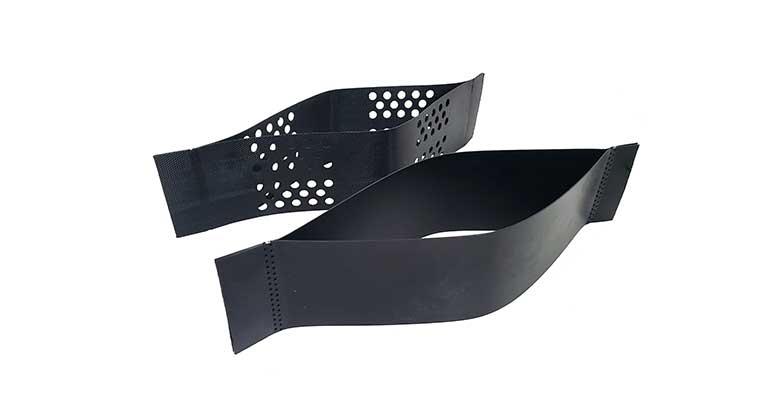

High-Strength Polyester Geogrid for Mining

Designed for mining applications, this high-strength polyester geogrid is enhanced with anti-static properties, high flame retardancy, and resistance to acids and alkalis. It is widely used forsupporting mine roofs and walls, and for reinforcement in tunn eling projects such as subways.

Basalt Fiber Geogrid

Basalt Fiber geogrid is made of basalt fiber by special knitting and surface coating process. It is applicable to the pavement reinforcement of High-speed expressway, bridges and airports, which can effectively avoid cracks, ruts and other diseases, effectively reduce the project cost, prolong the service life of the project and save the maintenance cost; It can also be used as reinforcing material of high-temperature composite materials and reinforcing material of building engineering and underground concealed engineering.

Smooth Geocell

After the raw materials are heated and extruded by the extruder, they are directly welded to form a smooth geocell. This is a smooth geocell. This kind of drainage performance is average, but the cost is low.After the raw materials are heated and extruded by the extruder, they are directly welded to form a smooth geocell. This is a smooth geocell.

HDEP Geocell

After the raw materials are heated and extruded by the extruder, they are directly welded to form a geocell. This is a geocell. This kind of drainage performance is average, but the cost is low.After the raw materials are heated and extruded by the extruder, they are directly welded to form a geocell.

Textured Geocell

After the rolling roller made of sheet welded into a patterned geocell, rolled polyethylene sheet made of the geocell can improve the inner friction between the geocell wall and the filling section, this application in the grid has many advantages: in the application of the cell super support, the larger geocell wall and the internal friction between the filling section can improve the vertical deformation of the border section relative to the grid geocell, thus making the vertical load vertical load to the surrounding geocell more effective transmission. The vertical cut load on the roadbed is reduced more than the smooth geocell, which further reduces the overall thickness of the roadbed.

HDPE geomembrane

Geomembranes are the impermeable geosynthetic products that have better physical, mechanical and chemical resistance properties protecting environment and water resources. Compared with traditional concrete, asphalt and compacted clay, geomembranes have proven to be far more effective, safe economic and fast deployment. They are widely used as canal, aquaculture, irrigation ponds and remediation liners, other lining applications include landfills, wastewater treatment lagoons, oil and gas exploration, etc.

EVA Geomembrane

GeoGro EVA Geomembrane is a waterproof and anti-seepage material made from synthetic resins EVA as the base material, with the addition of antioxidants, UV absorbers, colorants and other auxiliary materials.

EVA Geomembrane have high elongation, good low-temperature performance, and are soft and easy to apply.

Composite Geomembrane

GeoGro Composite Geomembrane is composited by filament geotextile or short fibre geotextile and geomembrane by hot compound. It has excellent flat drainage and anti-seepage property. It can be divided into one geotextile plus one geomembrane and two geotextile plus one geomembrane.

Smooth Geomembrane

Smooth geomembrane usually refers to HDPE geomembrane, which is a kind of high molecular polyethylene material, made by co-extrusion technology, with high molecular density, extremely low liquid permeability, and excellent anti-permeability effect. It has excellent chemical stability, anti-aging, anti-ultraviolet, anti-decomposition ability, can be used naked, and the service life of the material can reach 50-70 years. This kind of geomembrane has a smooth surface,low coefficient of friction and low cost

Textured Geomembrane

The textured geomembrane is composed of a concave-convex structure with a high friction coefficient. Compared with the smooth surface geomembrane, the rough surface geomembrane can not only be used for roof leakage prevention, landscaping, seepage prevention and water and soil conservation of farmland water channels, beach reclamation, landfilling in environmental engineering, three waste treatment and environmental remediation, prevention Desertification and other projects can also be used in engineering projects that require large friction coefficients such as steep slopes or side slope membrane surfaces that need to be covered with soil. It is the preferred material for engineering projects such as mountain construction and steep slope construction.

Pond liner

The pond liner produced by GeoGro can be used for long-term maintenance-free use after the laying is completed; it will not produce harmful substances that harm plants and fish in the pond; it can adapt to structural deformation such as uneven settlement without cracking; it is convenient and quick to construct.

The materials commonly used for pond lining are hdpe, epdm, pvc.

Filament Geotextile

GeoGro's Polyester filament geotextile is made directly by spinning and needle-punching and consolidating polyester filaments, it's made by forming and consolidating polyester filaments, the fibers are arranged in a 3D structure.Polyester filament non-woven geotextile has excellent heat resistance and light resistance, even if it is exposed to an environment of nearly 20 degrees for a short time, its performance is almost unchanged. After a large number of tests and practices, the polyester filament non-woven geotextile has long-term corrosion resistance to various natural soils, moisture and microorganisms.

PET Woven Geotextile

PET Woven Geotextile is interwoven by high tenacity PET filament yarn into a dimensionally stable network. The inherent characteristics of Polyester-high tensile strength and modulus,low elongation, low creep and high long-term design strength makes the good ideal for soil reinforcement application. The fabric develops excellent frictional interaction with a wide variety of soil and granular materials.

Polypropylene Geotextile

GeoGro PP filament spunbond needle punched nonwoven geotextile uses polypropylene as raw materials, is processed by spinning, airflow laying, needle punching and other processes

Polyester Geotextile

GeoGro Polyester Geotextile is Continuous Filament Needle punched non-woven Geotextile made from Polyester, formed by the process of needle punching and thermally bounding, offers optimum performance per unit weight. GeoGro Non-woven Geotextile provides effective and economical solution of separation, filtration, drainage, protection and reinforcement functions for engineering projects.